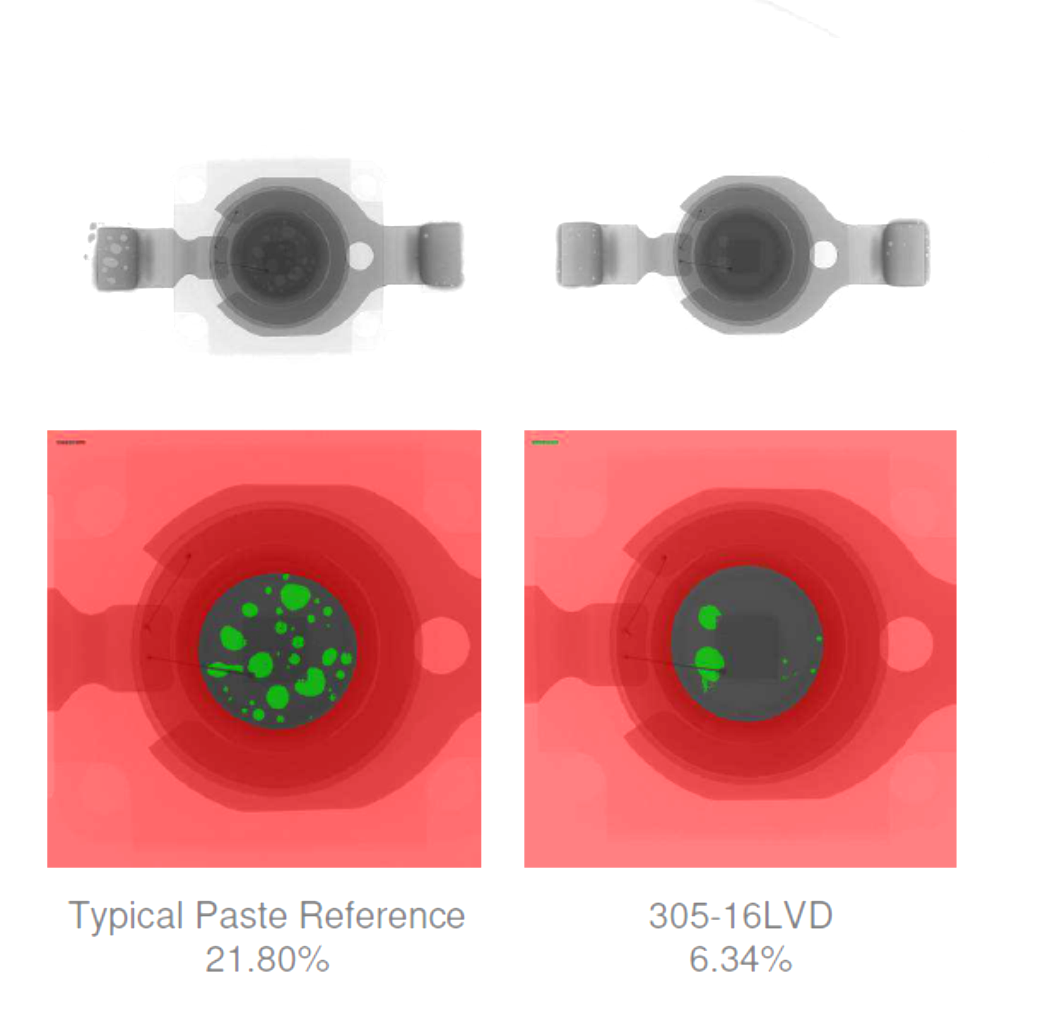

ECOREL™ 305-16LVD is especially designed by Inventec to reduce the dimension and amount of voids. This is especially beneficial when soldering bottom terminated components and for applications where excellent thermal management is crucial. A reduction of voids contributes to a better heat dissipation, more reliable electrical connection and a better intermetallic solder joint strength.

The solder paste ECOREL™ 305-16LVD is furthermore well balanced in terms of wettability, reliability, good compatibility with most conformal coating in the market and transparent clear residues. Besides the type 4 solder paste formulations are made from 100% recycled metals and paste in jar packaging can be stored at room temperature, which contributes to an overall reduction in CO2 emissions.

Features:

- Low voiding to offer great heat dissipation

- Very good wetting on all surface finishes, including OSP

- Transparent colorless residue, even after multiple reflow cycles

- Lead Free

- No halogen

- Free of CMR containing substances.

Application:

The best process will depend on factors such as operating conditions, equipment, board or component design.

Solder paste preparation:

- Put the paste at room temperature for at least 4 hours prior to use

- Before printing, it is essential to properly mix the solder paste, either manually with a spatula or by doing several preliminary prints on the stencil

- Automatic solder paste mixing is neither required nor advised.

Packaging:

- 250g & 500g jar

- 600g & 1200g cartridge

- 30g & 100g syringe